Subsections of Lydia - Printhead Documentation

Installation

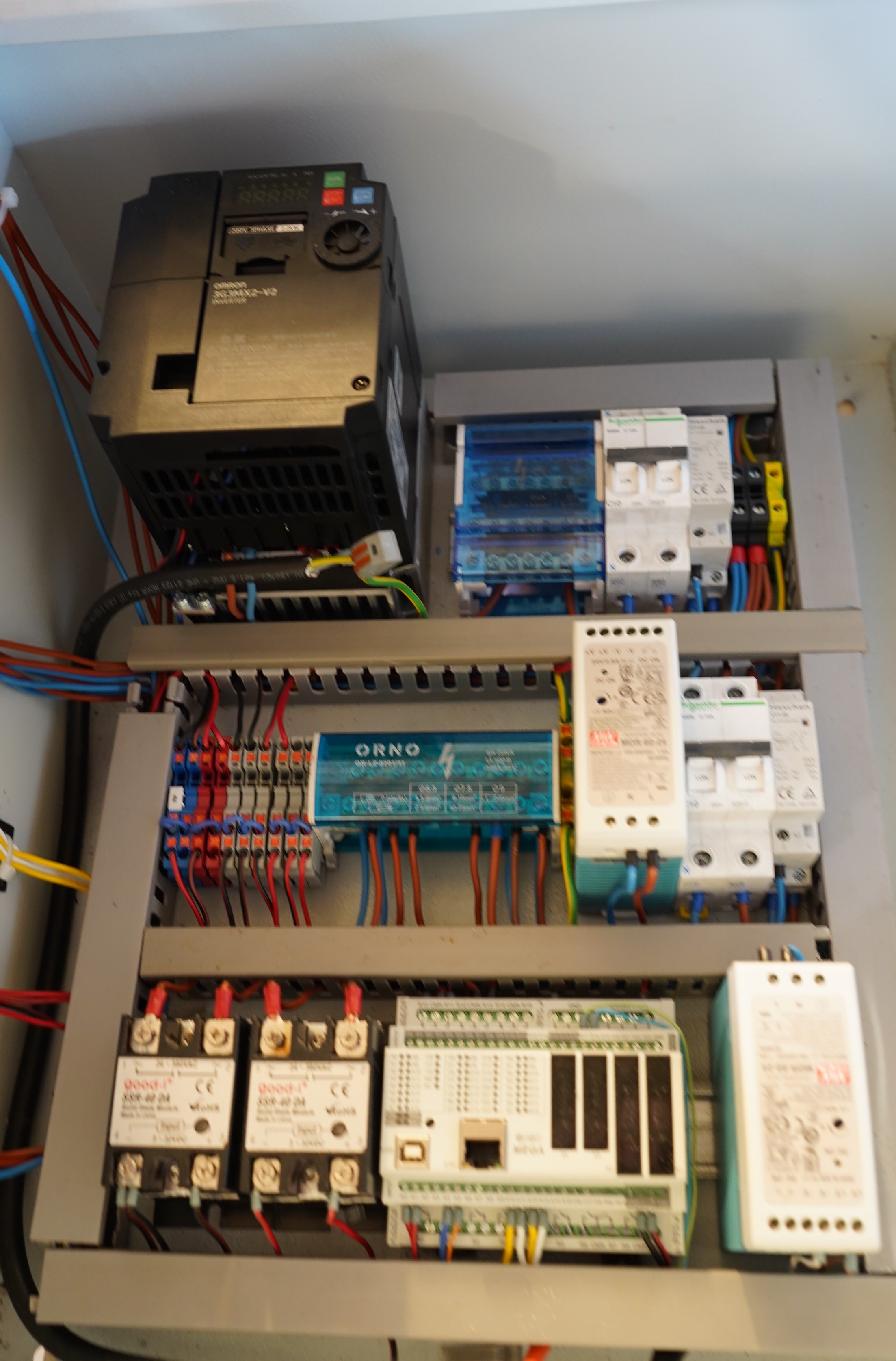

Omron MX2

- Please refer to the OmronMX2 - Modbus setup guide../vendor/omron/P641-E1-01_EGuide_CJ_Mod485_OMRON_3G3MX2-V1.pdf(Section 7.2.2)

In case the terminal labels mismatch the documentation, please use SN for (A-) and SP for (B+)

1.1 Set basic parameters

- Max. Frequency, depending on gearbox, A004 = 75Hz

- Acceleration time, F02 = 2secs

- Deceleration time, F03 = 2secs

- Output current on AM terminal (connect L to circuit GND!) as 10V : C28=01

- Enable Brake - A051 = 01 (../vendor/omron/I570-E2-02B.pdf : Page 105)

- The firmware expects the VFD at Slave-Address 1 !

Additionally, please check the user manual../vendor/omron/I570-E2-02B.pdf)

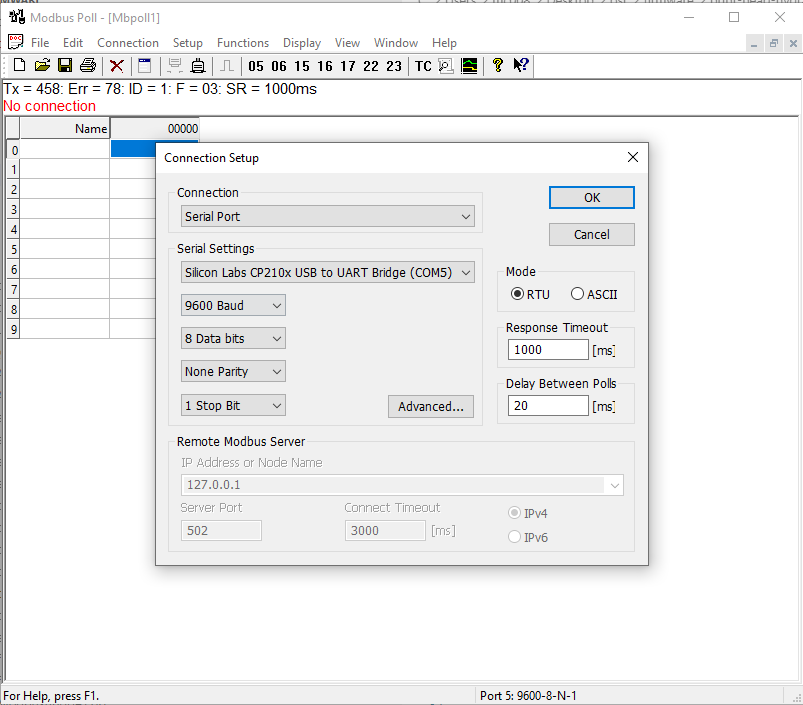

2.1 Modbus settings - Page 297

- Parity : None -

C74= 00 - Speed : 9600 -

C71= 5 - Slave Id : 1 -

C72= 1

2.2 Control settings

- Frequency selection -

A001: 03 (Modbus) - Command selection -

A002: 03 (Modbus)

Please restart the inverter after changing those settings!

2.3 Test settings, using serial Modbus adapter CP2102 and Modbus poll (see ./tools/MbPoll_v9.4.0_cracked.exe)

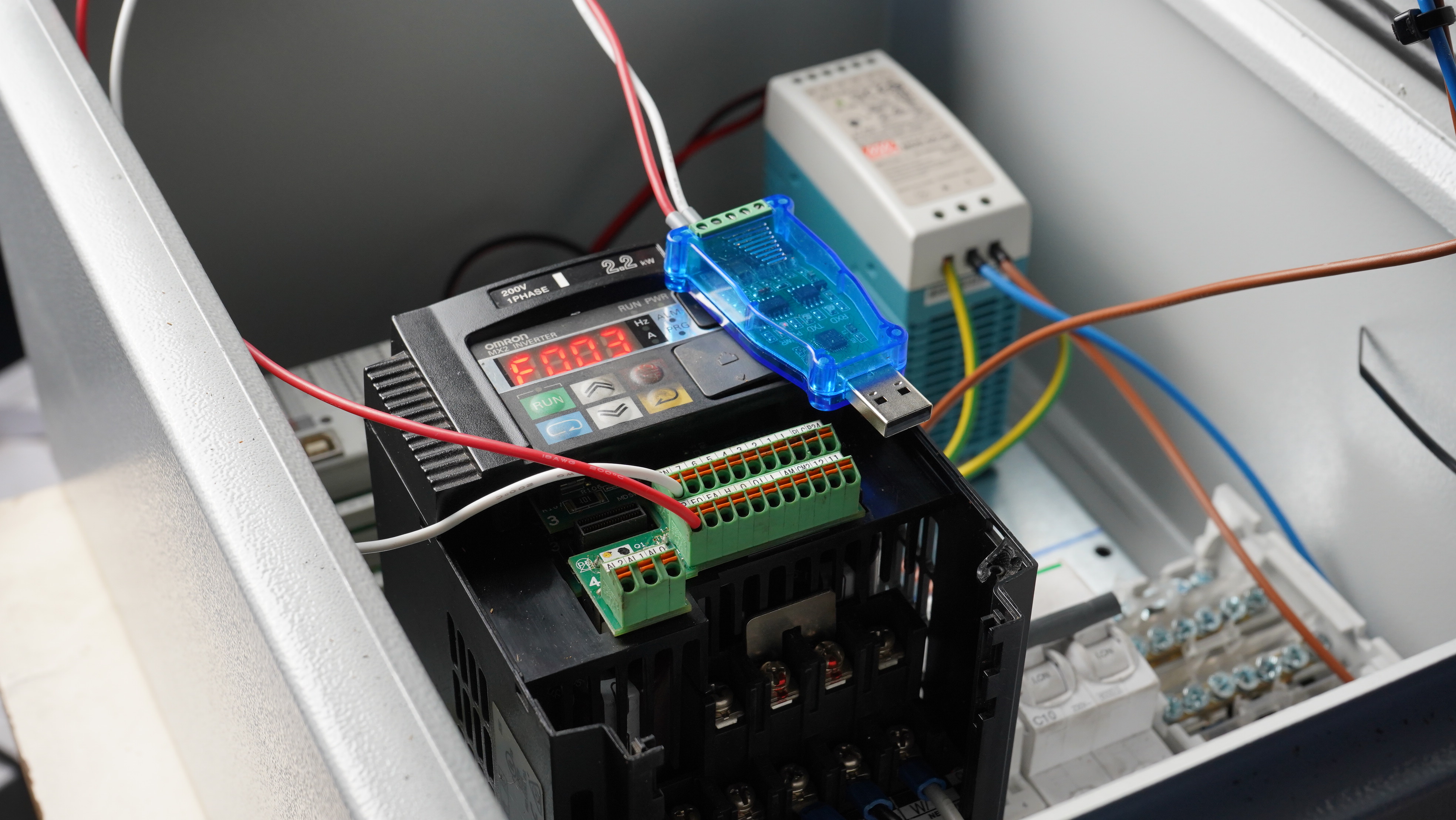

2.3.1 Wire the CP2102 USB adapter

2.3.2 Connect

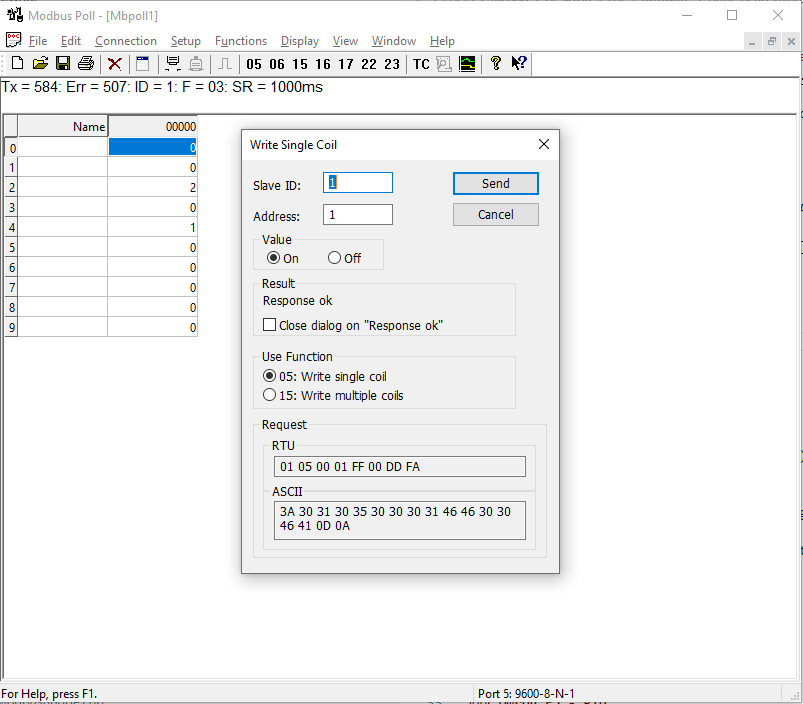

2.3.3 Function - Write Coil

The ‘Run’ LED shoud now be on.

Omron E5 - PID

TCP interface

To set the target temperature to 100 Degc on PID1, the complete message for Modbus TCP would be

01 06 00 11 00 64 D8 24

01: slave id06: Modbus verb / function code, in this case WRITE HOLDING REGISTER11: address (17)00 64: value (100), 2 bytesD8 24: CRC, 2 bytes. Since it’s TCP, this isn’t evaluated and can be ignored on the Controllino - PlasticHub firmware (see ‘./firmware/Mudbus.cpp’](./firmware/Mudbus.cpp)).

In order to fake a Modbus message, all we need is 01 06 00 11 00 64 but we also have to prefix it with the TCP overhead (d2 8d 00 00 00 06)

|—- TCP Overhead—– | ——– Modbus —- |

d2 8d 00 00 00 06 | 01 06 00 11 00 64

In example, we can send this via Hercules :

The TCP overhead (d2 8d 00 00 00 06) is created as follow:

d2 8d: Transaction identifier, 2 bytes00 00: Protocol identifier, 2 bytes00 06: Length of the message, 2 bytes

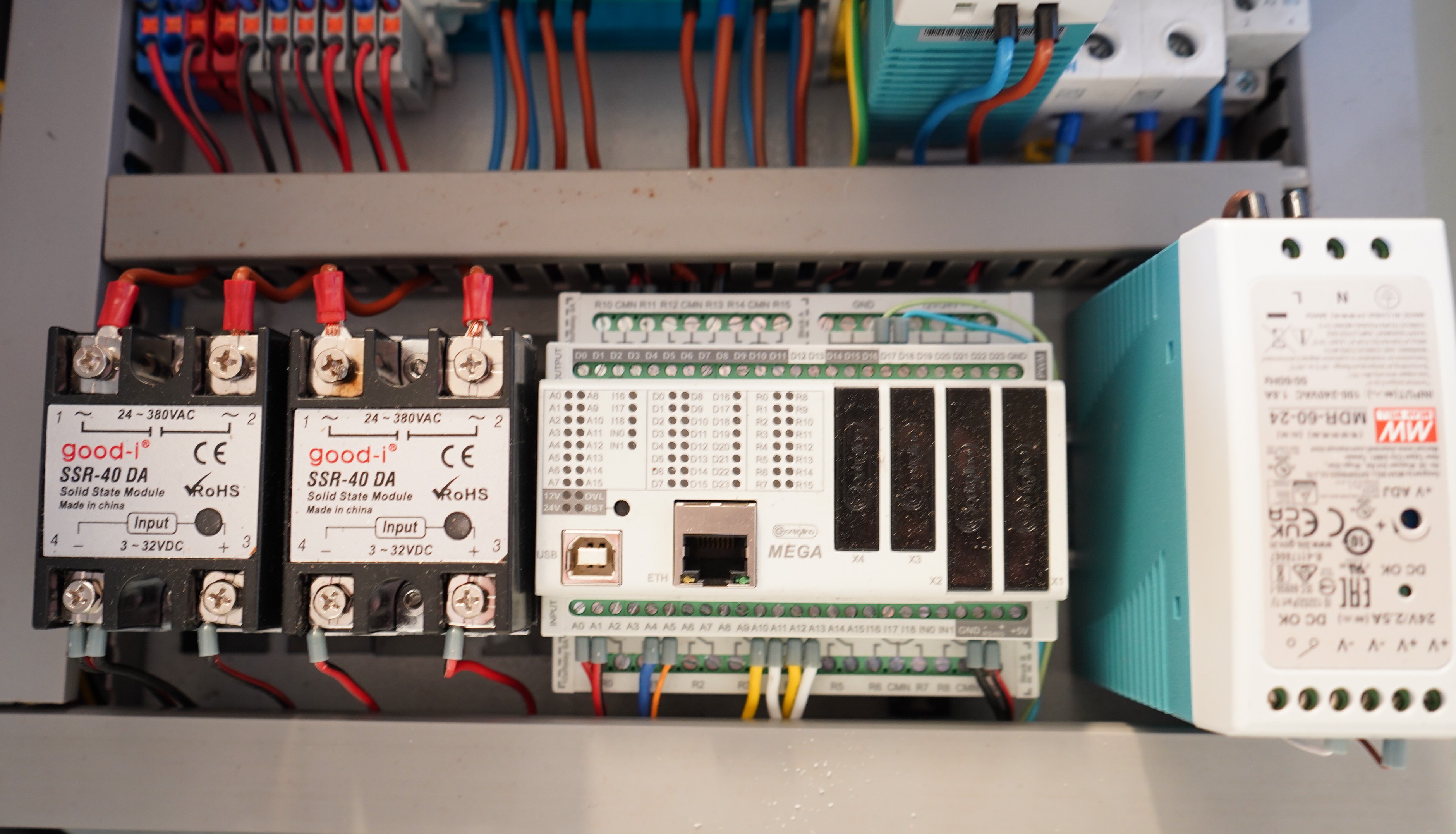

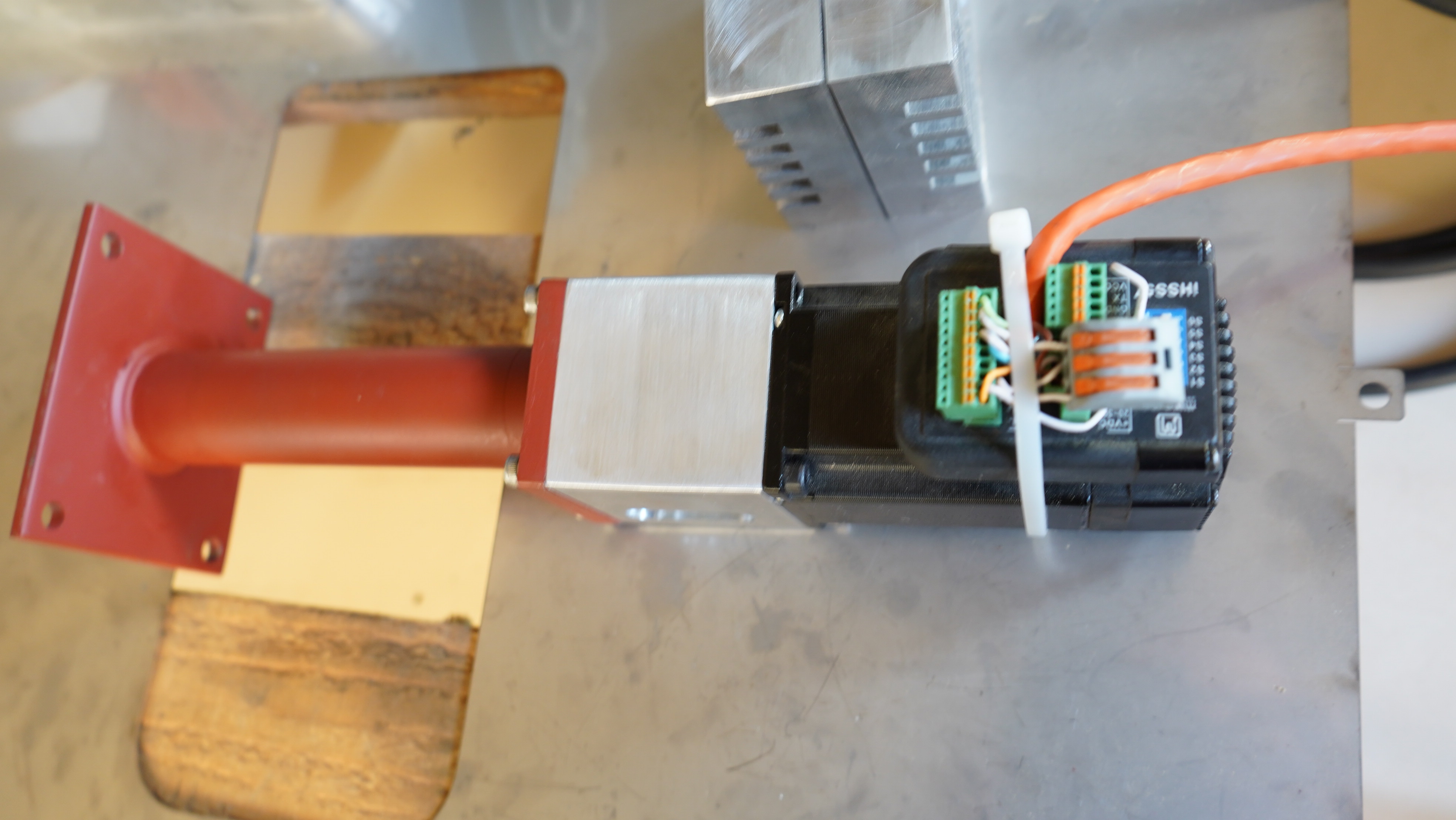

Clearpath - Teknic Servo

-> White (Input A+) -> DIR -> (MB_STEPPER_DIR_0 -> CONTROLLINO_D18)

-> Black (Input B+) -> PULSE -> (MB_STEPPER_PULSE_0 -> CONTROLLINO_D17)

-> Blue (Enable +) -> 24V

-> YELLOW (Input B-) -> GND

-> Brown (Input A-) -> GND

-> Orrange (Enable B-) -> GND

### Omron - Optional

- [Brake Resistor](https://www.farnell.com/datasheets/2923188.pdf)Subsections of Installation

Omron Setup

Modbus

Modbus - Documentation

Common

The controller exposes a Modbus ‘Master’ at the specified TCP interface on port 502.

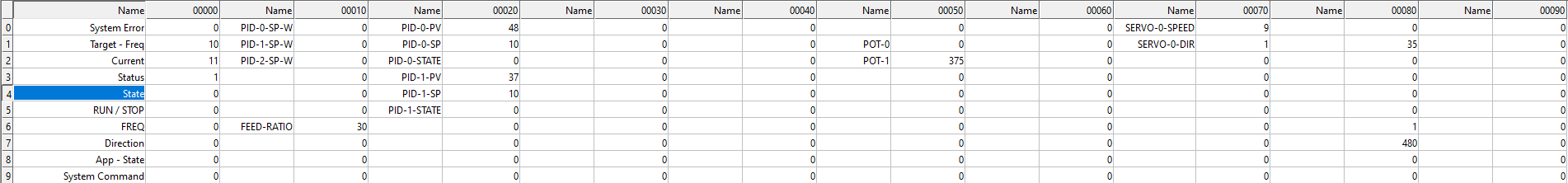

There are dedicated registers for the VFD, PIDs and internal values.

System Registers

| Name | Component ID | Address | RW | Function Code | Value | Register Description |

|---|---|---|---|---|---|---|

| System | 1 | 9 | -W | 0x6 | 1 | Print Modbus Queue |

| System | 1 | 9 | -W | 0x6 | 2 | Print Component Modbus Registers |

| System | 1 | 100 | -W | 0x6 | 1 | Reset Controller |

| System | 1 | 19 | -W | 0x6 | 1 | Print PID controller states |

Remarks

- Implementation for these calls : short ModbusBridge::loop() ./ModbusBridge.cpp

- It requires a USB cable connected, with 19200 bauds, 8 bits, no parity and 1 stop bit. You can use Arduino’s ‘Serial Monitor’ to see the output.

VFD Registers

The VFD (Omron - MX2) is being polled and controlled via RS485 at a defined Modbus slave address (Default 1). See more about the setup here.

| Name | Component ID | Address | RW | Function Code | Value | Register Description |

|---|---|---|---|---|---|---|

| VFD | 200 | 5 | -W | 0x6 | 1 | Set VFD in RUN mode |

| VFD | 200 | 5 | -W | 0x6 | 2 | Set VFD in STOP mode |

| VFD | 200 | 5 | -W | 0x6 | 3 | Set VFD in RETRACT mode (stop and retract) |

| VFD | 200 | 6 | -W | 0x6 | 0-100 | VFD Target Frequency |

| VFD | 200 | 2 | -R | 0x6 | 0-100 | VFD Current Monitor |

| VFD | 200 | 3 | -R | 0x6 | - | VFD Status OMRON_STATUS_STOPPED=2 OMRON_STATUS_RUNNING=0 |

| VFD | 200 | 4 | -R | 0x6 | - | VFD State OMRON_STATE_ACCELERATING=4OMRON_STATE_DECELERATING=2 OMRON_STATE_RUNNING=3 OMRON_STATE_STOPPED=1 OMRON_STATE_ERROR=8 |

PID Registers

The PID controllers (Omron - EDC5) are being polled and controlled via RS485 at a defined Modbus slave address, starting by default from 4.

| Name | Component ID | Address | RW | Function Code | Value | Register Description |

|---|---|---|---|---|---|---|

| PID | 100 | 20 | R- | 0x6 | 0-Maximum Temperature (PV) |

PID-0 Temperature |

| PID | 100 | 21 | R- | 0x6 | 0-Maximum Temperature / Set Point | PID-0 Set Point (SP) |

| PID | 100 | 22 | R- | 0x6 | Status | PID-0-Status / Default State : ‘Is Heating’ |

| PID | 100 | 23 | R- | 0x6 | 0-Maximum Temperature (PV) |

PID-1 Temperature |

| PID | 100 | 24 | R- | 0x6 | 0-Maximum Temperature / Set Point | PID-1 Set Point (SP) |

| PID | 100 | 25 | R- | 0x6 | Status | PID-1-Status / Default State : ‘Is Heating’ |

Auxillary Registers (Sensors / Switches)

| Name | ID | Address | RW | Function Code | Number Addresses | Register Description |

|---|---|---|---|---|---|---|

| OmronPID | 100 | 20 | R- | 0x6 | 6 | |

| MB_Relay | 300 | 41 | RW | 1 | 1 | |

| MB_Relay | 301 | 42 | RW | 1 | 1 | |

| POT | 400 | 51 | R- | 3 | 1 | |

| POT | 401 | 52 | R- | 3 | 1 | |

| Pos3Analog | 501 | 61 | R- | 3 | 1 | - Read Position : Address=61(3D) -> [Up:1 Middle:0 Down:2] |

| Pos3Analog | 502 | 62 | R- | 3 | 1 | - Read Position : Address=62(3E) -> [Up:1 Middle:0 Down:2] |

| VFD | 200 | 5 | – | 3 | 1 | |

| Stepper | 601 | 70 | RW | -1 | 4 | |

| MotorLoad | 210 | 2 | R- | 3 | 1 | |

| Status - LED | 701 | 84 | RW | 3 | 1 | |

| Status - LED | 702 | 85 | RW | 3 | 1 |

Stepper

| Name | ID | Address | RW | Function Code | Value | Register Description |

|---|---|---|---|---|---|---|

| Stepper-0 | 601 | 70 | RW | 0x6 | 0-5000 | Stepper-Speed |

| Stepper-0 | 601 | 71 | RW | 0x6 | 0-1 | Stepper-Direction |

| Stepper-0 | 601 | 72 | R- | 0x6 | - | Stepper-Status |

| Stepper-0 | 601 | 72 | – | 0x6 | - | Stepper-User |

Feed - Servo

| Name | ID | Address | RW | Function Code | Value | Register Description |

|---|---|---|---|---|---|---|

| Feed - VFD - Ratio | 601 | 16 | -W | 0x6 | 0-100 | Stepper-Speed |

The servo is turned on automatically as soon the VFD starts running.

Tools

To monitor and control the system, please open printhead-poll.mbp with MbPoll_v9.4.0.exe

Simulate Modbus for Development

- Please use MbSlave_v7.3.0.exe to start a Modbus-RTU master on TCP. You can use the ModbusPoll app to verify your code.

References

Subsections of Modbus

Modbus - VFD Control

VFD

Start & Stop

Starts or stops the VFD, be aware that a target frequency has to be set as well

- Address : 5

- Function : 6 (WRITE_REGISTER)

- Values :

- On : 1

- Off : 2

TCP Sequence for Start

d2 8d 00 00 00 06 01 06 00 05 00 01

+ + + +

| | | |

| | | +----> Value (2 bytes) = 00 01

| | |

| | +----> Address (2 bytes) = 05 or 0x0005

| |

| +--> Function Code (Always 6)

|

+--> Slave - ID (Always 1)TCP Sequence for Stop

d2 8d 00 00 00 06 01 06 00 05 00 02

+ + + +

| | | |

| | | +----> Value (2 bytes) = 00 02

| | |

| | +----> Address (2 bytes) = 05 or 0x0005

| |

| +--> Function Code (Always 6)

|

+--> Slave - ID (Always 1)Frequency

Sets the target frequency

- Address : 6

- Function : 6 (WRITE_REGISTER)

- Values : 1 - 50

TCP Sequence for setting target frequency to 50 Hz

Remark : Please respect the max. main frequency setting on the inverter (settings)

d2 8d 00 00 00 06 01 06 00 05 00 32

+ + + +

| | | |

| | | +----> Value (2 bytes) = 00 32 (for 50Hz)

| | |

| | +----> Address (2 bytes) = 06 or 0x0006

| |

| +--> Function Code (Always 6)

|

+--> Slave - ID (Always 1)Direction

Sets the rotation

- Address : 7

- Function : 6 (WRITE_REGISTER)

- Values :

- Forward : 1

- Reverse : 2

- Stop : 3

TCP Sequence for setting direction : Forward

d2 8d 00 00 00 06 01 06 00 07 00 01

+ + + +

| | | |

| | | +----> Value (2 bytes) = 00 01

| | |

| | +----> Address (2 bytes) = 07 or 0x0006

| |

| +--> Function Code (Always 6)

|

+--> Slave - ID (Always 1)TCP Sequence for setting direction : Reverse

d2 8d 00 00 00 06 01 06 00 07 00 02

+ + + +

| | | |

| | | +----> Value (2 bytes) = 00 02

| | |

| | +----> Address (2 bytes) = 07 or 0x0006

| |

| +--> Function Code (Always 6)

|

+--> Slave - ID (Always 1)Modbus - PID Control

PID Controllers

The PID controller target temperatures can be set as follows:

- PID 1 : Address 10

- PID 2 : Address 11

- PID 3 : Address 12

Set Target temperature on PID 1 to 100Degc

- Address : 10 (

0x10) - Function : 6 (WRITE_REGISTER)

- Values : 0 - Max Temperature (280)

TCP Sequence

d2 8d 00 00 00 06 01 06 00 0A 00 10

+ + + +

| | | |

| | | +----> Value (2 bytes) = 00 10 (16 Degc)

| | |

| | +----> Address (2 bytes) = 20 or 0x0014

| |

| +--> Function Code (Always 6)

|

+--> Slave - ID (Always 1)Set Target temperature on PID 2to 100Degc

- Address : 11 (

0x0B) - Function : 6 (WRITE_REGISTER)

- Values : 0 - Max Temperature (300)

TCP Sequence

d2 8d 00 00 00 06 01 06 00 0B 00 10

+ + + +

| | | |

| | | +----> Value (2 bytes) = 00 64 (100 Degc)

| | |

| | +----> Address (2 bytes) = 18 or 0x000B

| |

| +--> Function Code (Always 6)

|

+--> Slave - ID (Always 1)Set Target temperature on PID 3 to 100Degc

- Address : 12 (

0x0C) - Function : 6 (WRITE_REGISTER)

- Values : 0 - Max Temperature (300)

TCP Sequence

d2 8d 00 00 00 06 01 06 00 0C 00 10

+ + + +

| | | |

| | | +----> Value (2 bytes) = 00 10 (16 Degc)

| | |

| | +----> Address (2 bytes) = 0C or 0x000C

| |

| +--> Function Code (Always 6)

|

+--> Slave - ID (Always 1)Testing with Modbus Poll

Testing with Hercules

Modbus - Errors

Error Codes

The system exposes the current error code as a Modbus register at address 0x00 (FunctionCode:0x3) :

E_VFD_TIMEOUT= 1002E_PID_TIMEOUT= 2002E_FEED_OVERLOAD= 4001E_VFD_OVERLOAD= 1001

System Debug Commands

| Name | Component ID | Address | RW | Function Code | Value | Register Description |

|---|---|---|---|---|---|---|

| System | 1 | 9 | -W | 0x6 | 1 | Print Modbus Queue |

| System | 1 | 9 | -W | 0x6 | 2 | Print Component Modbus Registers |

| System | 1 | 100 | -W | 0x6 | 1 | Reset Controller |

| System | 1 | 19 | -W | 0x6 | 1 | Print PID controller states |

See more details in the PHApp::onError Implementation

Serial Interface

Serial Interface

Interfaces

Serial

All components provide minimal introspection capabilities : info, debug and custom registered methods. Each method can be called via Serial, eg : <<1;2;64;printRegisters:1:0>> to call ‘printRegisters’ for component 1 (main application).

Command construction :

Command Syntax : <<COMPONENT ID ; VERB ; FLAGS ; PAYLOAD>> whereby PAYLOAD consists out of METHOD:ARG-1:ARG-2

ID : Component Id

VERB : Command Type | Default=EC_METHOD (Class Method)

enum ECALLS

{

// global function

EC_COMMAND = 1,

// addon method

EC_METHOD = 2,

// external function

EC_FUNC = 3,

// user space

EC_USER = 10

};FLAGS : Flags being used for the call. Default = 64

enum MessageFlags

{

NEW = 1 << 1, // set on target when inbound

// set on target

PROCESSING = 1 << 2,

// set on target when inbound

PROCESSED = 1 << 3,

// set on host, turn on debugging through the entire processing chain

DEBUG = 1 << 4,

RECEIPT = 1 << 5 // set on host, this will return the new state

};PAYLOAD: String, this string depends on the verb, Default = Class::Method(short,short)

Modbus

Firmware

Requirements

Installation / Compile

Remarks

- Install the following Arduino libraries from the zip!

osr-fw-baseAccelStepperArduino_MemoryFreeArduinoLogVector- and

Controllinoas described below

Controllino - Mega

- Arduino - ‘Board’ Manager. See also here, the official documentation

- Navigate to File–>Preferences

- Copy-paste the following link to the Additional Boards Manager URLs:

- For MINI, MAXI & MEGA boards: https://raw.githubusercontent.com/CONTROLLINO-PLC/CONTROLLINO_Library/master/Boards/package_ControllinoHardware_index.json

- For MICRO boards: https://github.com/CONTROLLINO-PLC/controllino_rp2040_firmware/releases/download/global/package_controllino_rp2040_index.json

- Press OK button

- Then navigate to Tools–>Board–>Boards Manager

- In the Boards Manager type CONTROLLINO into the filter text box and search for CONTROLLINO boards (or for CONTROLLINO RP2040 boards in case of MICRO)

- When found, select the latest version and install it. The installation process should be fully automated

- When finished – check in Tools–>Board–> menu that you can see the CONTROLLINO boards there

- Arduino - Controllino Library

- Start Arduino IDE, navigate to Sketch–>Include Library–>Manage Libraries

- In the Library Manager type CONTROLLINO into the filter text box and search for CONTROLLINO library

- When found, select the latest version and install it. The installation process should be fully automated

- When finished – check in Sketch–>Include Library menu that you can see the CONTROLLINO library there

- You can also check if you can see the set of CONTROLLINO examples in File->Examples->CONTROLLINO

Configuration

IP Address

- Change IP Address from default 192.168.1.177 here

Serial Ports

- By default, the firmware is set to 19200, 8 Bits and no parity. That’s due to the limitation of it’s slowest components, Omron-E5DC PID. You can change the settings here ‘Modbus - Commons’